|

|

|

|

|

#1 |

|

Uber EcoRenovator

Join Date: Apr 2011

Location: Strathroy Ontario Canada

Posts: 657

Thanks: 9

Thanked 191 Times in 129 Posts

|

Vlad

I would agree. Most of us would rather play on the side of efficiency. My first attempt at the GSHP I was very pleased with the out-come. The little 2 Ton unit is operating seemingly well. (saving a pile of cash that was destin to the fuel oil mongers) Being ground source the evaporator temps and pressures are rock steady. The condensor side as well dosen't change more than 4 Deg C. When I had tweeked the charged the unit had been operating for hours so the temps had evened out. I had used my amp probe and temp probe on the high side tube before the HX to get the temp of the liquid/gas. I was looking for the highest temp and the best current for the optimum charge. The refrigerant is propane the pressures are 45 LS 210 HS and 86 Deg. C The 2 Ton unit is a little small for the shop and I've just finished a 3.5 Ton version to swap it out and again with cap tube. I'm understanding the theory behind the TXV changing the amount of restriction based on the temp of the evaporator. Do you think I would gain more efficiency with the TXV if the temps and pressures are so steady. Even on start -ups the temps don,t change much after about 10 min. I'm at a point where I can still cut out the cap tube and replace it with a TXV. I realize we may tend to be a little barbaric in our methods as we learn hands on. But we do appreciate direction from people in the know. Thanks Vlad Randen |

|

|

|

|

|

#2 |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

AC thanks for starting drilling thread. Manifesto became a monster thread . It is very hard to find something here. I will upload all info and pics about my drilling experience there.

It would be good to have some kind of summary of the project (may be separate page or thread ) not a discussion but timeline. We have many projects started here and they all mixed up together. It is almost impossible follow your project or somebody else project. People keep asking the same questions you keep re-posting.... It is just an idea. |

|

|

|

|

|

#3 |

|

Apprentice EcoRenovator

Join Date: Aug 2010

Location: Windsor ON Canada

Posts: 229

Thanks: 4

Thanked 30 Times in 22 Posts

|

I found this easy explanation about TXV function.

HVAC/R Everything You Need To Know About TX Valves When it comes to TXVs they are very complicated devises but they make your system run more efficient and safer for compressor. Most of them are adjustable so, to change your superheat you don't need to open system again (cap tube case, what a pain) but just adjust it. Nobody asks you to know all functions and all details about txv. You just need to know how to select one and how to adjust it. |

|

|

|

| The Following User Says Thank You to Vlad For This Useful Post: | AC_Hacker (02-26-12) |

|

|

#4 |

|

Helper EcoRenovator

Join Date: Jun 2011

Location: Norway

Posts: 63

Thanks: 3

Thanked 10 Times in 10 Posts

|

Hi guys.

I have been very busy for a long time now. Regarding Arduino stuff, I said earlier that I could help out if someone needed it. I have yet to receive any questions, but still AC said that there was little help to be found in this area. I would like to contest that. Please let me know what you need, and I will mock up a circuit and some software that will do what you want. I am pretty sure that I can make anything you need in a very short time. This is what I do for a living at the moment, embedded systems. For others to get ideas, I suggest posting the requirements here. Something like: Three temperature inputs, T1, T2 and T3 - Readout to serial interface every second --- T1 is indoor temperature --- T2 is outdoor temperature --- T3 is accumulator tank temperature Three relay outputs, R1, R2 and R3 - R1 goes on 20 seconds before R2, and stops 20 seconds after --- water pump for ground loop - R2 goes on when T1 <= 40C and off when T1 >= 50C --- Used for starting/stopping compressor --- Never run for more than 30 minutes --- Minimum pause of 10 minutes if the full 30 minutes are reached (deicing of ASHP?) - R3 comes on if R1 is running and T3 is not increasing (driving alarm buzzer) (did not bother to figure out how to format bullet-point lists here, sorry) This is all just random stuff i thought up right now, you need to figure out what you want. If you want to start a pump for solar collectors at a given temperature, use the solar collector as source for the heat pump, trough solenoid valves want to divert waterflow to a outdoor water HX to get higher input temperature when outdoor temperature is higher than the ground loop etc. All of this is quite easy logic, and I believe I can make software that will be easily extendable and understandable. The circuitry will be very simple indeed. Temperature measurement is a matter of connecting a tri-leg transistor like thingamabob to ground, +5V and one of the arduino inputs. If you need negative temperature, you must add a diode. Output is a resistor, transistor and relay. It is all very simple, I am certain all of you will be able to do it, just let me know what you need. -Morgan- |

|

|

|

|

|

#5 | |

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

This is really great! I would say that one of the most basic requirements would be a delayed compressor ON relay, that would protect against intermittent voltage events. So, it would be a delay with a duration of about 2 minutes after current ON, before the compressor relay switches on. I see SSRs for sale cheap on ebay, theoretically one would last for a long time. I am not sure of the efficiency of a SSR, though. Some solid state power devices leak current in the 'off' state, some don't deliver full current in the 'on' state. What is your opinion here? Is there a way to protect electro-mechanical relay's contacts from degradation due to arcing? Another feature would be in the case of a water-source heat pump. It would need to monitor the temperature of water going from the ground loop into the evaporator HX... If the water gets too close to freezing as it is coming out of the the HX (this would depend on anti-freeze percentage), it will freeze and quite likely damage the HX. Another would be a way to monitor over-pressure in the compressor, an do an emergency power-down if over-pressure occurred. Your other ideas look very good, too. -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... |

|

|

|

|

|

|

#6 |

|

Helper EcoRenovator

Join Date: Jun 2011

Location: Norway

Posts: 63

Thanks: 3

Thanked 10 Times in 10 Posts

|

AC, that should be easy enough to do. Sparkfun carries some current measurement devices, but what kind of pressure sensors would you use? Any other ideas?

Regarding SSR and electro-mechanical. The SSR does have a voltage drop across it. Ususally SSRs have something like 1.5V drop. Pulling 1A will give you 1*1.5=1.5W heat loss. Not a whole lot, but with more current you will get more wattage lost, and potentially a need for cooling. On the other hand, the EMR will not have any of this. If you switch one cycle every hour of every day for a year, you have done 8760 cycles in a year. Take for instance this: LINK It has an electrical life of 100000 operations at max rated load, 10 million without load, so somewhere in between if you do not pull full power. That should last the lifetime of the unit. If not, you could always change to a SSR later if it does not work well. It is not expensive to replace. I would go for EMR. Temperature measurement of the loop water will be easy enough to fix. Seems like a state machine design is brewing here. |

|

|

|

|

|

#7 |

|

Less usage=Cheaper bills

Join Date: Nov 2010

Location: Minneapolis, MN

Posts: 939

Thanks: 41

Thanked 116 Times in 90 Posts

|

If you are protecting against an intermittent voltage event, can't you just set something simple up on the low voltage side, if you lose power, just cut the thermostat connection for 2 minutes. It would save a ton of hassle, wouldn't it?

|

|

|

|

|

|

#8 | ||

|

Supreme EcoRenovator

Join Date: Mar 2009

Location: Portland, OR

Posts: 4,004

Thanks: 303

Thanked 723 Times in 534 Posts

|

Quote:

Quote:

Regarding the exact type of pressure sensor (switch?) I'm not so sure. I do know that they are included in commercial equipment. I also don't know what the over pressure limit we would want to set as a limit for R-290. I'm hoping BradC and/or Vlad might have some information for us on this issue. Also, BradC indicated that in calculating superheat, that there is a way to do it with just temperature measurement. Perhaps there is a way to protect the compressor from over-pressure that only uses temperature measurement, too? Sounds good to me. Do we need to include a diode or cap to prevent contact arcing? -AC_Hacker

__________________

I'm not an HVAC technician. In fact, I'm barely even a hacker... Last edited by AC_Hacker; 02-28-12 at 09:46 AM.. |

||

|

|

|

|

|

#9 | |

|

Apprentice EcoRenovator

Join Date: Dec 2010

Location: Western Australia

Posts: 148

Thanks: 1

Thanked 48 Times in 34 Posts

|

Quote:

Something like these : Search Result Automatic Controls : Detail | Saginomiya Seisakusho, Inc. They are about $20 list at my local fridge place. Do not make it a software function. It must knock out the compressor. These are even better, as they must be reset manually : REFRIGERATION HIGH PRESSURE CONTROL : HLP530ME | eBay Available pretty much everywhere and fully adjustable. Your HP cut out should be sized for a fault condition only. Because I condense at 26Deg C, I set mine at ~180 PSI, which is about 40 Deg C. On my Air cooled unit, the HPCO is set at 360 PSI, which is about 65 Deg C for R22 (which the unit was designed for). Pick an appropriate safety margin and aim for that. Use the closest matching fixed switch you can find. You really should pressure test your high side to about 1.3 times the pressure the HPCO is set at. For example, mine is set at 40C. On a stinking summers day here, with the system not running and in the direct sun, the ambient is going to rise _above_ 40C. I could see potential pressures above 55C in the system with it sitting idle. So you need to account and test for your worst possible case. |

|

|

|

|

|

|

#10 | |

|

Lex Parsimoniae

Join Date: Feb 2009

Location: Woburn, MA

Posts: 4,918

Thanks: 114

Thanked 250 Times in 230 Posts

|

Quote:

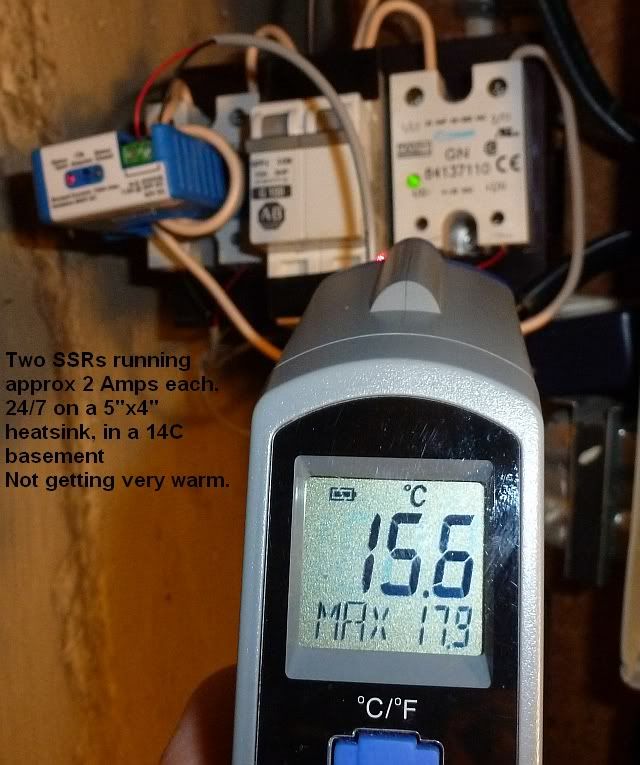

I've been using SSRs on my Sanyo ASHPs and they don't seem to heat up their heat sinks much at all. Slightly warm to the touch maybe.. SSR:  Maybe it's just too cool in my basement for the heat sink to store much heat.?. The back side of the sink has some short cooling fins. Even in summer, I don't think a fan will ever be needed in this application. When it's really cold, the typical current increases to 4 or 5 amps. But, the heat sink never really gets much warmer than it is this morning.. Sanyo #2 uses a single SSR mounted to it's sheet metal chassis. http://i46.photobucket.com/albums/f1...CL/afterBH.jpg Heat Scan during the late summer showed no noticeable heat increase. I guess the chassis is too large and has too much air flow to warm up. EMR: (Before hack) http://i46.photobucket.com/albums/f1...L/BeforeBH.jpg We do get current surges up to 10 amps. Anything above 10A triggers the sensor and shuts down the system for about 60 seconds. Anyone thinking of using R290 should consider using SSRs, instead of relays. Unless the relays are considered safe to use in a propane-air environment. I'm not an expert, but it just seems like common sense to avoid sparks with some gases.

__________________

My hobby is installing & trying to repair mini-splits EPA 608 Type 1 Technician Certification ~ 5 lbs or less.. Last edited by Xringer; 03-01-12 at 07:16 AM.. Reason: R290 |

|

|

|

|

|

| Tags |

| air conditioner, diy, gshp, heat pump, homemade |

|

|